Health care workers across the nation are struggling with a shortage of personal protective gear, or PPE, as COVID-19 continues to spread across communities. In Reno, a network of makers is coming together to help fill those needs with 3D printing technology.

At The Lab

Nicole Miller wears many hats. She’s a mixed media visual artist and manager of the Art Fabrication Laboratory at the University of Nevada, Reno, which opened up about a year ago. She’s also a maker: Someone who is constantly looking for creative ways to solve challenges. Someone ready to get their hands on any kind of project to build a solution.

At the lab, Miller can batch cut about 25 pieces of fabric in roughly 15 minutes, after digitizing Renown Regional Medical Center’s sanctioned mask pattern. She then drops off material to UNR students and faculty who are volunteering their time to sew the masks together.

“With something like this, you feel like you can't work fast enough. You want to get in and start producing content. And you need to shift gears and change the way you think and the way work,” Miller said.

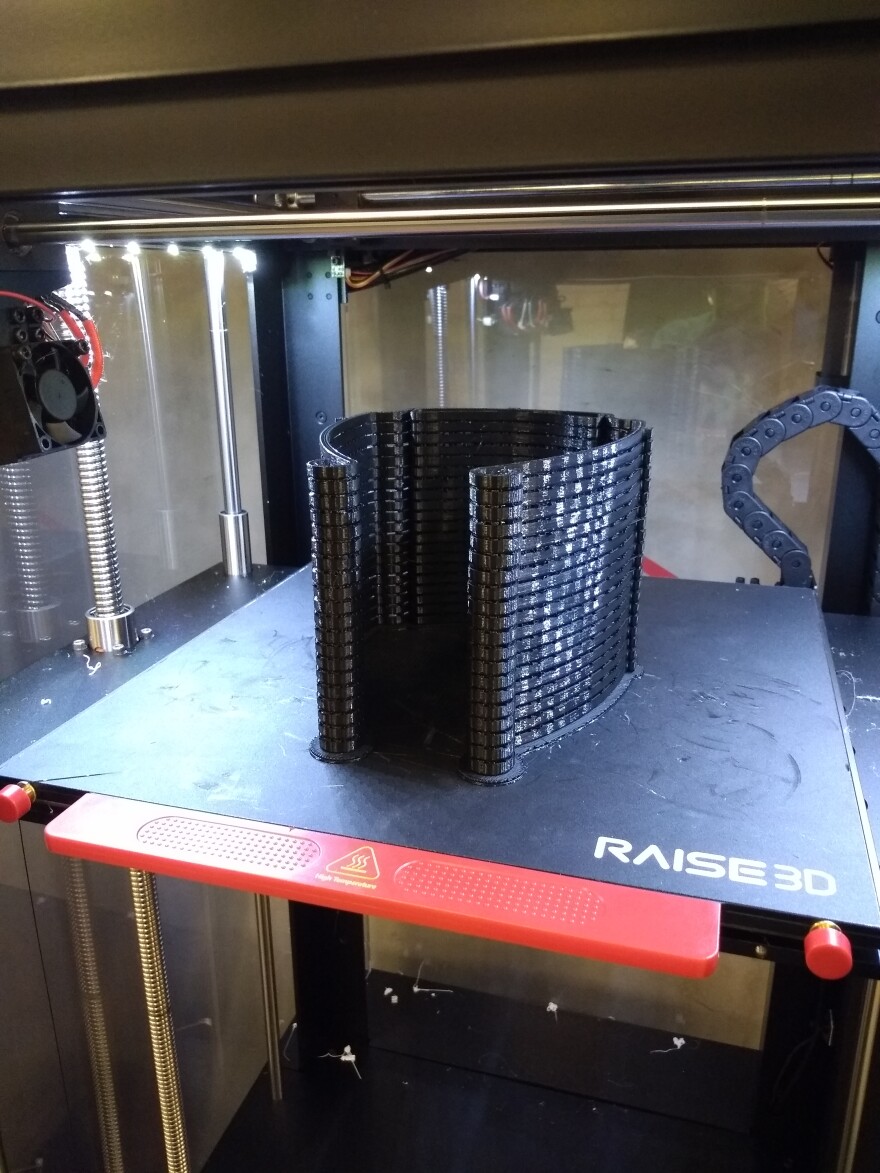

On top of face masks, Miller is contributing to the production of 3D-printed protective visors, modeled by an open-source project from Sweden. These face shields are washable, reusable and they go over the face mask and are meant to protect people from COVID-19 droplets.

A face shield can take up to an hour or so to make and can cost anywhere from 75 cents to a dollar.

Miller is the lone wolf working in the lab, but for others, their workspace might look a little different.

Working From Home

Daniel Smith is a makerspace specialist at the University of Nevada, Reno’s Innevation Center.

“I actually took some of the equipment home with me,” Smith said. “It's all set up in my garage, which was already a mix of workspace between myself and all of my roommates, so we had to push a lot of the stuff to the side.”

Smith was a lead in starting this effort.

“When this all started breaking out, I was looking at different projects we can do and then a member from the history department, Chris Church, reached out to a large number of us. So he started an email chain, which was the start of our little community,” Smith said. “That was starting to get a little unwieldy, so I helped him set up a slack channel so we could invite more people in and keep our communications more organized.”

Now he’s coordinating with nearly 40 other community members to get the job done.

Health care facilities can request the 3D-printed PPE online at Griffin Co. Miniatures and Gifts. The company quickly shifted its business model. Before the pandemic, they supplied 3D-printed pieces for tabletop games, like Dungeons and Dragons, but now they’re dedicating their time to produce PPE, manage hospital requests, and to distribute them.

At the beginning of this effort, many people used their own spare materials, but now the donor alumni relations department at UNR has set up a crowdfunding source. The donations help purchase materials like ABS filament, the plastic used to make the face shields. Collectively, nearly 1,500 face shields are being made a week.

Smith isn’t the only maker setting timers to check in on 3D-printed PPE at home.

“What was my computer desk has become an ad hoc 3D-printing station. It's really a 2-by-4-foot space where the 3D printer has taken over. There's a small collection of tools and then the supplies needed to do the 3D printing,” Nick Crowl said.

Crowl is the manager of the DeLaMare Science and Engineering Library on campus.

He said in the beginning, hospitals weren’t accepting maker-made materials, but things have changed. Now the group of makers has seen more than 7,000 requests.

“I think the concept of 3D printing is still a little bit mystical to a lot of people that don't do this every day, even though it's a very simple thing to do,” Crowl said. “Unless you have a real reason to go hands-on with the software, there is a big disconnection. In reality, the computer is the one doing the majority of the work. It's not unlike sending a normal document to a printer.”

Click here to support KUNR’s COVID-19 coverage.

Rural Nevada

A dozen hospitals in rural Nevada requested 2,500 face shields.

Jason Bleak is the administrator and CEO of Battle Mountain General Hospital.

“Some of the key supplies are very difficult to replace. Gloves are difficult to replace. The general earloop nursing masks are very difficult to replace and also the medical gowns,” Bleak explained. “We still have a level of alertness because we can't replace them as quickly as we have in the past. All of our critical needs supplies have been put on allocation, so even if we order 10 cases of one item, they will only allocate maybe one case per month.”

Bleak said anxiety looms in and around the hospital, but he has seen every medical provider step up for the community.

Joan Hill is the president of Nevada Rural Hospitals, which works to provide 12 rural hospitals with health care necessities. She said these hospitals are isolated and face financial hurdles.

“We serve only 10% of Nevada's populations, but in 90% of the landmass. So we are distant from each other and distant from tertiary areas. Most of our payer source is mostly Medicare or Medicaid, so we are always on that fine line of profitability,” Hill said.

During the pandemic, rural hospitals are seeing help from makers — like those in Reno — who are now working on developing new projects, like isolation gowns, materials for testing and disposable clothes.

As a note of disclosure, the license to this station is owned by the Board of Regents for the Nevada System of Higher Education.